G-Eco Heat Pumps – From Delivery to Commissioning

What should be considered when installing a G-Eco heat pump using R290 refrigerant?

Environmental friendliness and energy efficiency are becoming increasingly important in both building construction and technical building systems. R290, or propane, is a refrigerant that effectively meets both needs. In this article, we go through what to consider when installing a G-Eco heat pump that uses R290 refrigerant – from transport to commissioning.

Why R290?

R290 is a natural refrigerant with a near-zero climate impact compared to traditional HFC refrigerants – its GWP (Global Warming Potential) is only 0.02, and it contains no harmful, persistent PFAS compounds. R290 heat pumps are suitable for use in current heating and cooling systems.

In addition, the thermodynamic properties of R290 make it an excellent choice for heat pumps: it enables a high COP, high supply water temperatures, and efficient heat transfer – which translates into energy savings for the end user. Compared to commonly used R410A refrigerant, R290 operates at lower system pressures, reducing stress on components and improving reliability. Read more about the R290 features.

Transport and Placement

Transporting a G-Eco heat pump to the site can be done using standard freight and does not require handling as dangerous goods (ADR).

Transport the heat pump to the installation site preferably using a pallet truck or a similar tool. If using a crane, the unit can be lifted with two lifting straps or slings rated for the unit’s weight. Protect the painted surfaces of the heat pump with a soft cloth or similar material to prevent the straps from damaging the finish. Ensure the straps stay securely in place throughout the lift. The safety of the lifting procedure must be planned in advance and is the responsibility of the site performing the installation.

When choosing the installation location, it is important to ensure that operating noise does not disturb the heated property. The heat pump and associated piping should not be installed directly against structural elements, as this can transmit vibrations and noise. Gebwell offers octave band sound measurements to support acoustic planning, which can be utilized during system design.

G-Eco series heat pumps are equipped with a ventilated enclosure solution, where air is directed out of the building from the refrigerant circuit’s influence zone. The heat pump includes an exhaust air duct and an exhaust fan. This ventilated casing is a reliable safety solution when using a flammable refrigerant.

The safety of heat pumps is ensured by limiting the maximum refrigerant charge according to flammability and toxicity thresholds. The refrigerant charge in G-Eco heat pumps is below the maximum allowed for ventilated enclosure solutions in terms of flammability, which allows more flexible placement in the building.

R290 is non-toxic, but in large quantities it can displace oxygen if released into air, which sets volume requirements for the installation space. For the G-Eco Core 40, the minimum room volume is 20 m³, and for the G-Eco Pro 120, it is 54.5 m³ when installed in occupied rooms. “Occupied rooms” refers to spaces such as former bicycle storage rooms that are repurposed for heat pump installation.

R290 heat pumps differ from those using synthetic refrigerants in terms of maintenance. During service work that requires opening the refrigerant circuit, an area classification is created around the heat pump, and any electrical devices in the vicinity must be de-energized. Therefore, it is recommended to place devices with sufficient spacing, if space allows. Heat pumps should be positioned to minimize disruption to building operations during servicing. At least one meter of clearance should be maintained, especially from electrical cabinets and backup heating equipment.

Installing the G-Eco Heat Pump

Installing a G-Eco heat pump does not require any special certifications from the installer. The R290-based G-Eco heat pump is very similar to Gebwell’s existing heat pump models that use synthetic refrigerants. The added safety feature in G-Eco models is the exhaust ducting, which has not been widely used in heat pumps before. It is recommended to begin piping installations with the exhaust fan and ductwork, so that the system can be brought under automation control as early as possible.

Electrical connections must be carried out by an authorized electrician. Using R290 refrigerant does not require changes to standard electrical wiring practices, apart from the additional connections for the exhaust fan. The exhaust fan receives power from a distribution board and control signals from the heat pump.

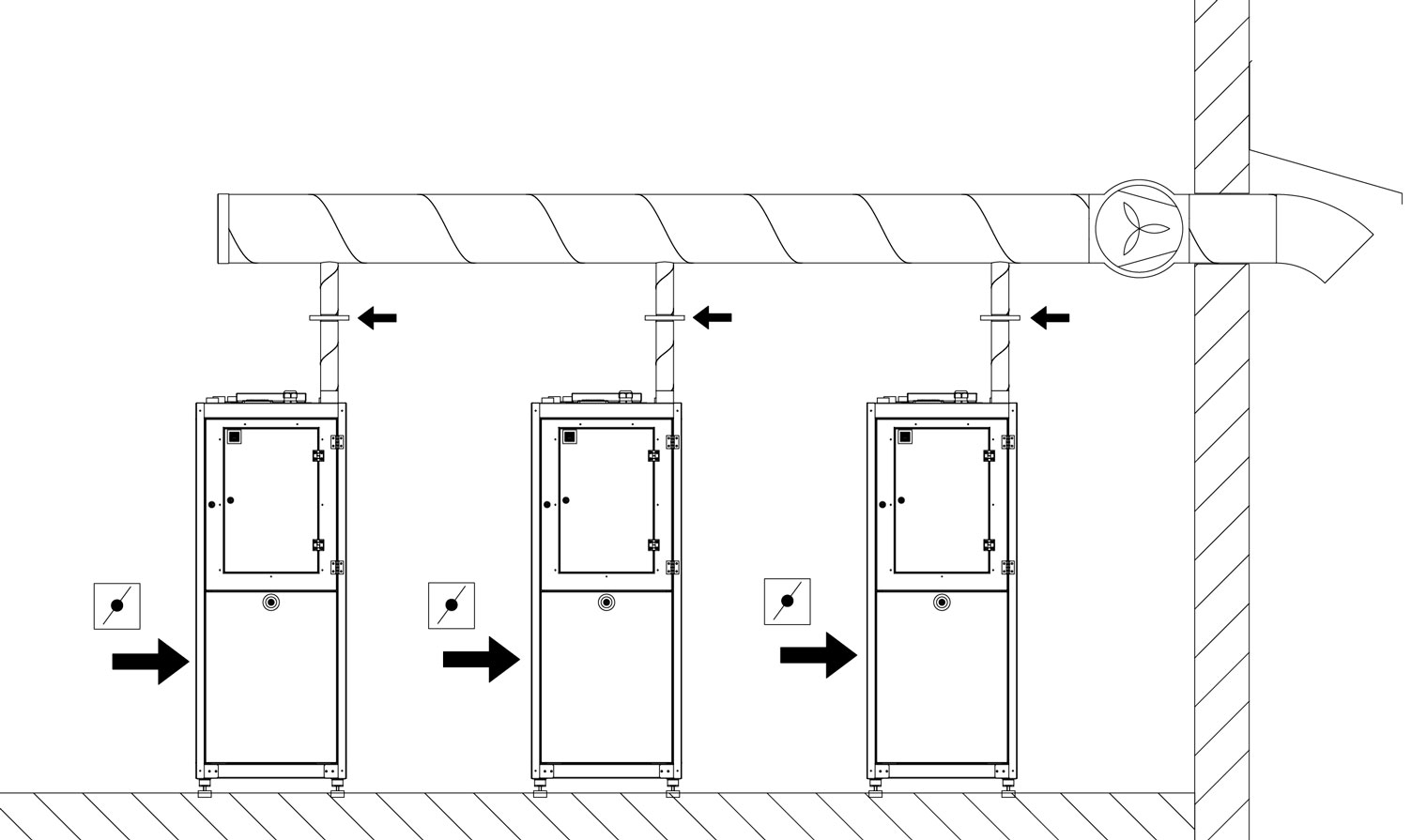

A maximum of three G-Eco heat pumps can be connected to the same exhaust duct with a single exhaust fan. If needed, individual units can be equipped with their own fans. The direction of exhaust airflow must be assessed case by case, and the outlet must be clearly marked.

Since R290 is a flammable refrigerant, all intermediate circuits must be properly protected. This ensures that the refrigerant does not reach occupied areas of the building.

Commissioning the Heat Pump

Before starting the heat pump, it is important to ensure that all installations and connections are completed according to diagrams and instructions. It must also be verified that all air has been properly purged from the network to guarantee trouble-free operation.

G-Eco heat pumps are equipped with an exhaust ducting system, which must be implemented and verified according to our instructions.

Summary

G-Eco heat pumps offer significant advantages in terms of flow temperature, energy efficiency, and climate impact. Installing a Gebwell G-Eco heat pump is largely similar to installing our existing models, but the flammable nature of the refrigerant requires special attention to safety.

For many professionals in the field, the ventilated enclosure solution used in G-Eco heat pumps may be a new concept. During installation, special care should be taken to ensure correct implementation of the exhaust duct system and fan, as well as protection of intermediate circuits.

When regulations and manufacturer instructions are followed carefully, G-Eco heat pumps are a safe, efficient, and environmentally friendly choice for modern heating systems.