The fossil oil heating at Kämmenniemi School was replaced by ecological geothermal energy

Kämmenniemi School in Tampere abandoned oil heating and switched to climate-safe geothermal energy. The new system uses the natural refrigerant R290, providing a sustainable and energy-efficient heating solution for the school and daycare far into the future.

The renovation of the school’s oil-based heating system had been under consideration for over ten years. During the long planning process, several alternatives were assessed – including lake heat, wood chips and pellets.

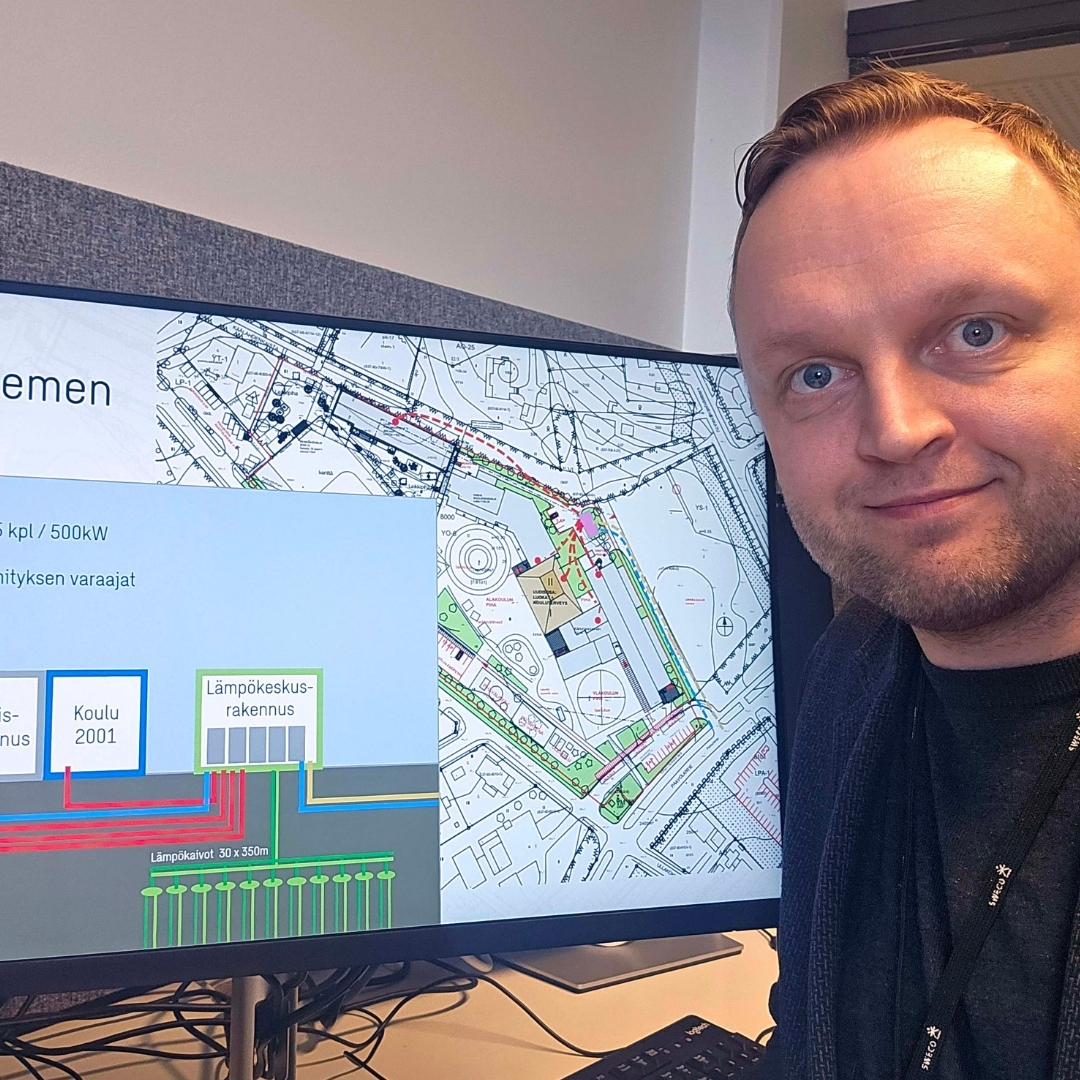

“We decided on geothermal energy because we wanted an environmentally friendly and future-proof solution. Key factors were the City of Tampere’s goal to phase out oil heating, a 40 % state subsidy for the project and low life-cycle costs. In comparison, wood chips or pellets would still have required oil as a support fuel,” says Timo Heikkilä, Leading Specialist at Sweco Finland, responsible for the system design.

School to be renovated for 600 pupils

The first building of Kämmenniemi School was built in 1969, with extensions completed in 1988 and 2001, and a daycare facility added in 2019. In addition to the daycare, preschool, primary and lower secondary school, the property complex also houses a library and youth centre.

A major renovation project will be carried out in two phases, the first starting next year. After the renovation, the school will accommodate up to 600 pupils and preschoolers.

The total heated area of the school and daycare buildings is just over 8,000 m². The geothermal source consists of 30 boreholes, each 350 m deep. A separate 73 m² heating plant was built on site to house the heating system.

G-Eco geothermal system ready for free cooling

The heating system is a 520 kW G-Eco installation, consisting of four G-Eco Pro 120 heat pumps and one G-Eco Core 40 heat pump. The G-Eco Pro units provide space heating, while the G-Eco Core unit produces domestic hot water at a higher supply temperature.

“The system also includes a 3,000-litre G-Energy Custom buffer tank for heating and a 3,000-litre G-Energy Coil tank equipped with seven vertical coils for domestic hot water production,” explains Kalle Kanninen, Managing Director of North Energy Solutions Oy, which carried out the installation. A backup electric boiler was also installed in the system.

The system is also prepared for geothermal cooling.

“Currently, only space cooling is in use – geothermal cooling is used to cool the heating plant. Once the school renovation is complete, geothermal cooling and exhaust air heat recovery will also be introduced in the school buildings,” Kanninen adds.

Designed with the updated F-gas regulation in mind

The system design included G-Eco heat pumps using natural R290 refrigerant from the outset.

“From the beginning, I planned the system taking into account the upcoming F-gas regulation and PFAS restrictions. It was known that natural-refrigerant commercial heat pumps were already available on the market, making it possible to design a future-proof geothermal solution,” Heikkilä explains.

“We had good prior experience with Gebwell from an earlier project. Their reliable after-sales service and technical support gave confidence to design the system with propane-based equipment. In practice, if technical support is only available abroad, troubleshooting can become difficult,” he continues, noting that the system connections and operation were reviewed with Gebwell already at the design stage.

Heikkilä also praises the installation company:

“We were fortunate to have North Energy Solutions as the contractor – based on this project, they have proven to be a competent and easy-to-work-with heat pump system supplier.”

Manufacturer support and remote commissioning praised

The Kämmenniemi School project was the first geothermal system implemented by North Energy Solutions using G-Eco heat pumps.

“Compared to conventional heat pumps, the main difference was the implementation of ATEX ventilation and ducting required by the propane refrigerant, as well as connecting the vent lines from air bleed valves to the ventilation ducts. The separate heating plant, located away from passage routes, allowed individual ventilation and fans for each heat pump – which differs from standard practice,” Kanninen explains.

The system was commissioned in August 2025.

“We received remote commissioning support from Gebwell, and the start-up went smoothly. We were always able to reach technical support when needed. After initial adjustments, the system has been running well — and there was even less fine-tuning required than expected,” Kanninen concludes, recommending G-Eco heat pumps for similar projects.

Site and system details

- Heated area: over 8,000 m²

- Designed for 600 preschoolers and pupils

- 30 × 350 m geothermal boreholes

- 520 kW geothermal system: 4 × G-Eco Pro 120 + 1 × G-Eco Core 40

- 3,000 L heating buffer tank and 3,000 L domestic hot water tank

- Readiness for geothermal cooling